- The Overlanding Crowd

- Posts

- Alu-Cab (2000), company history deep-dive

Alu-Cab (2000), company history deep-dive

Plus, some consumer insights from Overland Expo

Hi, Overlanding Crowd. And welcome to our third chapter.

As a quick reminder, this is a free weekly B2B newsletter which will delve into the companies in the space via a weekly deep-dive, as well as trends, tactics and innovation in our specific niche. And the niche we focus on encompasses Overlanding, Van-Life and Vehicle Based Camping.

This week, in Chapter 3, we focus on a deep-dive into Alu-Cab, the legendary South African Overlanding brand which has become an ever-present in the industry. We also digest some of the stats from Overland Expo West.

By the way, I’m heading on a road trip to Spain and France with my family this week, spending some time in campsites, some time wild camping, and some time in a house! So I’ll be chatting to consumers along the way and keeping an eye out for any interesting rigs.. I’ll come back with anything that I think may be of interest to the community.

PS - if you’re new here or have been forwarded this email, you can sign up for the free newsletter here:

And please share if you like what we do. It helps enormously to drive down our cost or reader acquisition.

"Nothing behind me, everything ahead of me, as is ever so on the road" - Jack Kerouac

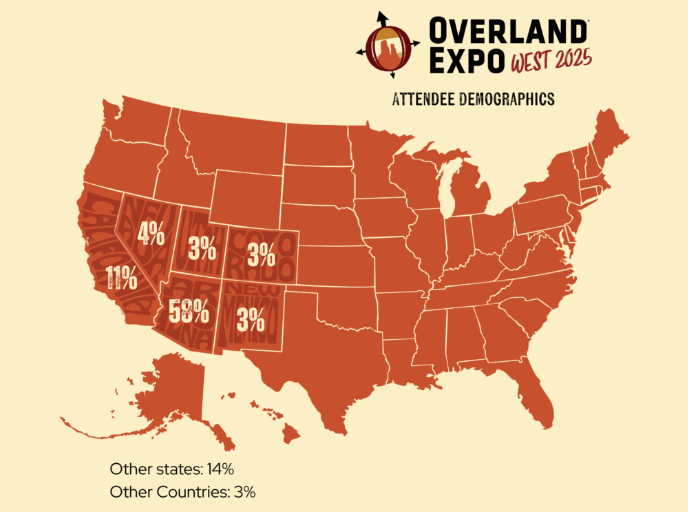

Data from Overland Expo that’s worth digesting

I spoke to a couple of the guys from Overland Expo during the week and I’ll have more insights next week First here are some of the headline stats from the West..

Overlanders aren’t just about vehicles—they’re multi-activity outdoor enthusiasts: hiking, biking, paddling, learning skills. Exact figures next week.

Education is central: Over 60% of sessions teach survival, driving, or navigation skills with huge interest levels.

Family and stewardship matter—events centered on kids and cleanup efforts reflect community-focused values.

New growth continues: with 41% newcomers at Expo West 2025, the audience remains fresh and opportunity-rich.

Also interesting to see that the (ambitious) 15,000 expected attendees at the new show in South Cal earlier in the year actually became 19,000. This is a niche with growing interest, and one which has huge head-room. Plus, Emerald are getting the mix right here between consumer experience and a little trade. Maybe this can be used with OR???

Alu‑Cab: From a Cape Town Garage to the Roof of the World

If you’ve been reading our newsletters for a while, you’ll know that I think most of the best gear stories don’t start with a pitch deck or a trade show—they start with someone annoyed by bad equipment. That’s exactly how Alu‑Cab began.

It was the early 2000s, and Jeremy Thor Bergh, a South African plumber with a passion for 4x4 travel, was getting fed up. The steel canopy on the back of his bakkie (pickup) was rusting, heavy, and awkward to use. On his weekend trips into the bush, it rattled, leaked, and got in the way. So, in true DIY fashion, Jeremy built his own—out of lightweight aluminum, with side-access panels for easy gear reach, and a layout that made sense for actual overlanding.

That garage project didn’t just solve his own problem. Friends noticed. Then customers followed. What Jeremy had created was one of the first aluminum side-opening canopies designed specifically for adventurers, not contractors.

And just like that, Alu‑Cab was born in 2000, right from a Cape Town garage—long before “overlanding” became a hashtag.

xoverland.com

Made for Overlanders—By One

Jeremy wasn’t thinking about branding or mass production at first. He just wanted better gear. But that very focus—on solving real problems with rugged simplicity—is what made Alu‑Cab resonate. Early on, adventurers, safari outfitters, and backcountry mechanics caught on: this was no ordinary canopy. It was field-ready, lightweight, and modular in ways other gear just wasn’t.

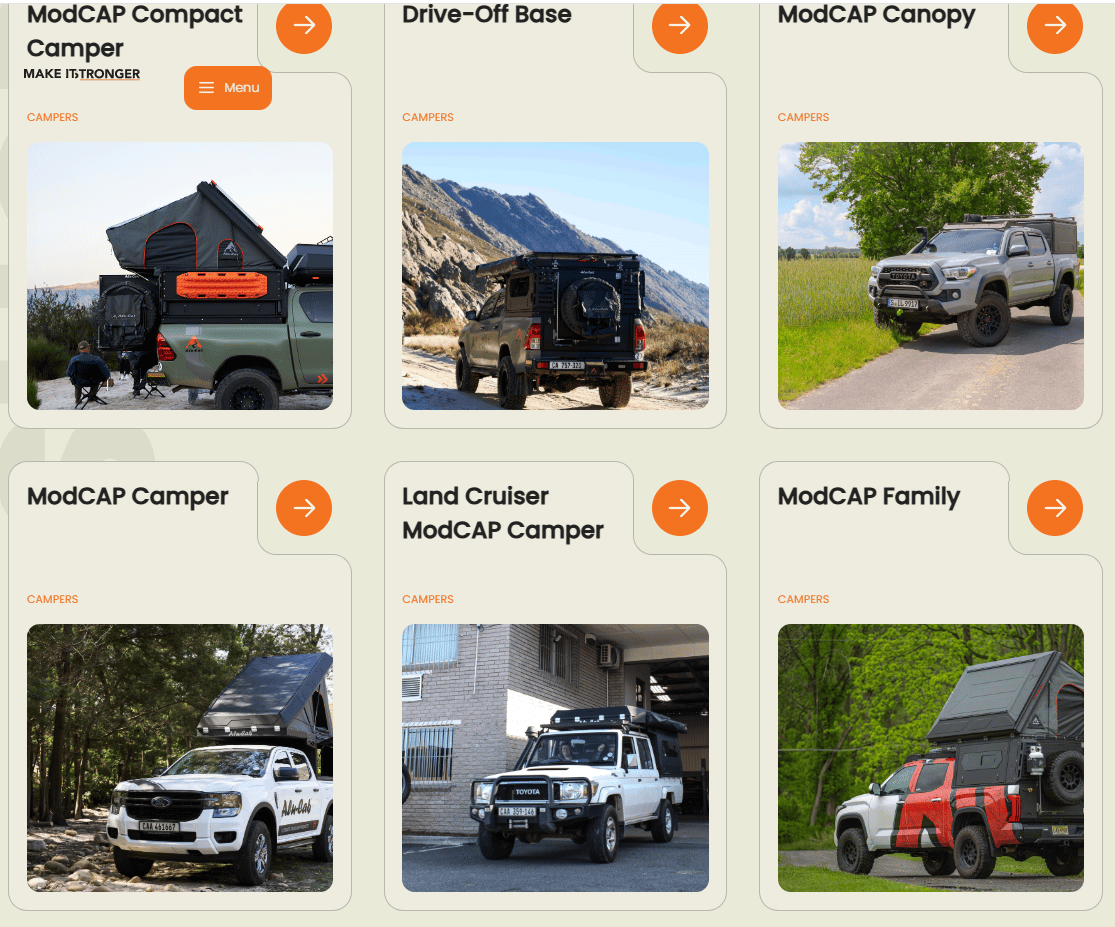

Soon, Jeremy was building more than just canopies. Customers began asking for add-ons—awnings, rooftop tents, drawers, mounts, and eventually full-on camper conversions. Alu‑Cab answered with gear that wasn’t just rugged—it was smart. Think gas-strut-assisted panels, weather-sealed roof tents, awnings that could stand up to the Namibian coast, and fridge slides that didn’t rattle themselves apart.

Every new product followed the same logic: designed in-house, tested in the field, and improved based on real user feedback. And because everything was built in South Africa, they could prototype and refine on the fly.

Fast forward two decades, and the company now has 10 production facilities, a Cape Town headquarters that includes R&D, manufacturing, fitment, and testing zones—and distribution to over 70 countries. From Patagonia to the Pacific Northwest, Alu‑Cab gear shows up wherever vehicles are driven hard.

Built in Cape Town, Trusted Worldwide

Even as the brand has scaled globally, one thing has stayed the same: almost everything is still built in Cape Town.

The decision to keep manufacturing local wasn’t just patriotic—it was strategic. By building everything in-house, from aluminum panels to canvas tents, Alu‑Cab keeps quality control tight and iteration fast. A team of over 400 employees—engineers, fabricators, upholsterers, QC inspectors—works under one coordinated system. New ideas can go from sketch to road test in days, not months.

It also means accountability. You can walk through their plant and meet the people welding hinges and stitching canvas. There’s pride in every piece that rolls out the door—and it shows.

Their gear is also incredibly modular. Buy a canopy, and you can mount a tent, awning, shower system, storage boxes, or fridge system. It’s like vehicle-based LEGO for grownups—only everything fits, lasts, and works off-grid.

That kind of integrated thinking has made Alu‑Cab especially popular among expedition drivers, tour companies, conservationists, and rescue crews—not just recreational overlanders. When a product gets used in the middle of nowhere, failure isn't an option. Alu‑Cab gear reflects that mindset.

Leadership and Legacy

In 2023, Jeremy stepped back from day-to-day operations after a health scare—but not out of the picture. He now serves as Chairman of the Board, focusing on product innovation and field testing. His passion remains as strong as ever—you’ll still find him sleeping in prototypes, cooking under new awnings, and tweaking tent hinges until they’re just right.

Day-to-day leadership now rests with Managing Director Warwick Leslie, a longtime team member who understands both the scale and soul of the business. Warwick has brought fresh structure to operations and dealer expansion while preserving the feedback loops and field-testing culture that made Alu‑Cab what it is.

It’s a partnership that works: Jeremy drives the vision, Warwick delivers the execution.

Revenue and Reach

Alu‑Cab is now considered the largest overlanding outfitter of its kind globally. Multiple independent sources estimate its annual revenue at around $60–65 million, with over 170 full-time direct employees and hundreds more across installation and distribution networks. That revenue puts them well ahead of North American rivals like Four Wheel Campers or Goose Gear.

They now ship to more than 300 dealers globally, and their products appear in OEM builds, expedition fleets, national parks, and even military vehicles. In the U.S., Alu‑Cab has grown rapidly over the past five years, helped by strategic partnerships with installers and fitment centers who mirror the brand’s exacting standards.

And it’s not just volume—it’s loyalty. Their customers tend to stay in the ecosystem, upgrading over time. Buy a canopy, then a tent. Then the drawer system. Then the shower cube. Alu‑Cab has built a platform, not just a product line.

What Makes Them Different

So what’s the magic behind Alu‑Cab’s rise?

Purpose-Driven Design – Every product starts with a real need and gets tested in real environments.

Local Manufacturing, Global Reach – Quality control is tight because it’s in their backyard.

Integrated Ecosystem – Products work together as a system, not a patchwork.

Constant Field Testing – Feedback loops from customers, explorers, and internal R&D shape ongoing improvements.

Scalable but Grounded – Despite their size, they still build gear like it matters—because it does.

You don’t hear much flash from Alu‑Cab. No influencer collabs. No lifestyle fluff. Just gear that works.

Looking Down the Road

The company isn’t slowing down. On the product front, they’re launching lighter rooftop tents, a four-sleeper tent for families, new weather-rated awnings, and an evolving fridge and kitchen system with slide-lock integration.

There’s also talk of a North American production facility, which would dramatically reduce lead times and shipping costs for U.S. customers. The goal? Serve the growing demand without diluting what makes the brand special.

And the overlanding world is watching. In an industry where style often outpaces substance, Alu‑Cab has quietly built a reputation as the gear you buy when you’re serious.

Final Word

Alu‑Cab isn’t just a brand. It’s the result of two decades of obsessive design, backcountry testing, and a deep understanding of what overlanding really requires. It started in a garage with a single canopy. Now, it’s a global platform with rugged gear trusted across continents.

But through it all, one thing hasn’t changed: it’s still gear made by people who use it—for people who rely on it.

And in the world of off-grid travel, that might be the most valuable feature of all.

Thanks for reading and I hope you find value in the newsletter. If you do, please share. It helps a lot. Also feel free to reach out directly with any thoughts or feedback (or interests in sponsoring / partnering) at [email protected]

Happy driving.

Until next week, go n-éirí leat!

Derek.